自动换刀贴标雕刻机

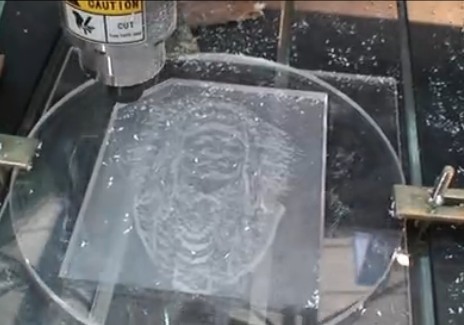

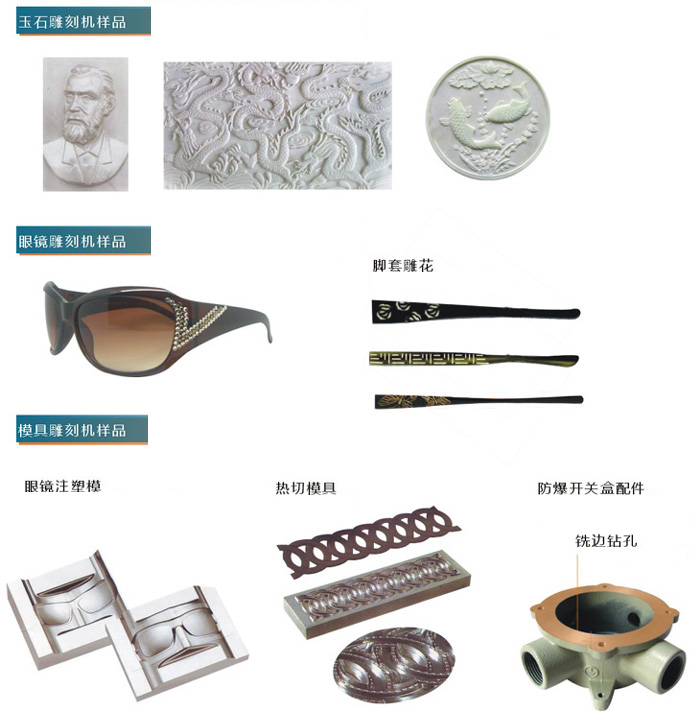

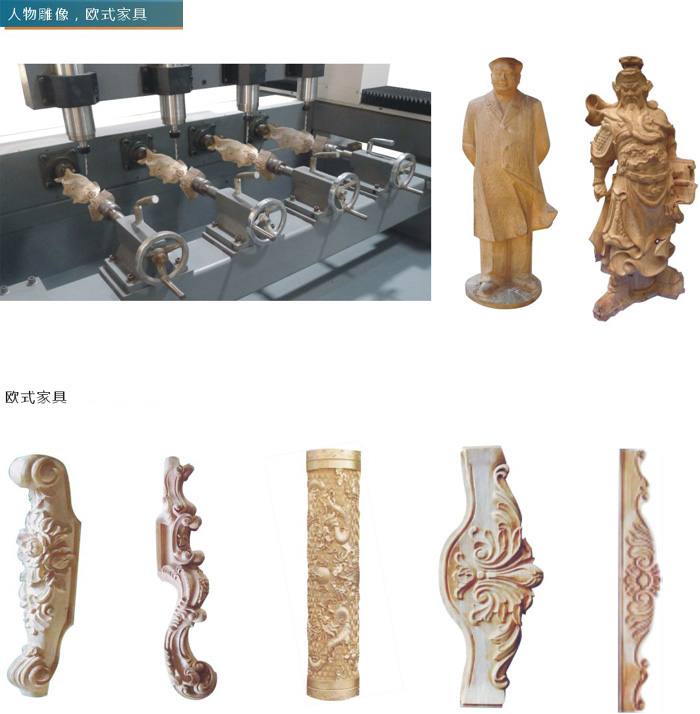

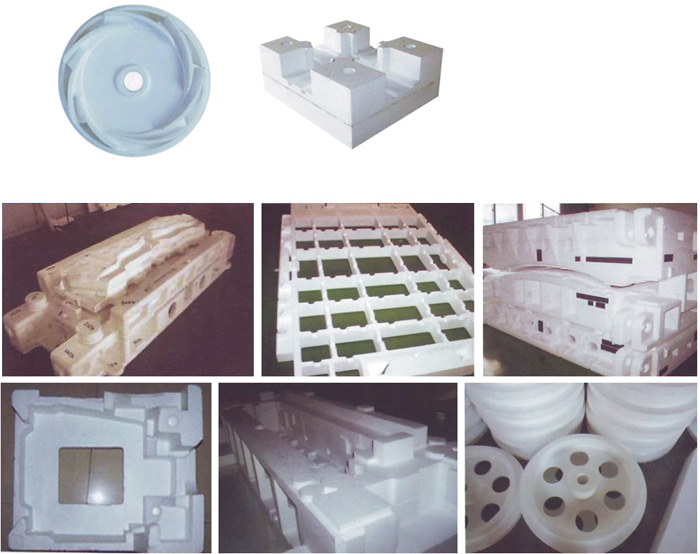

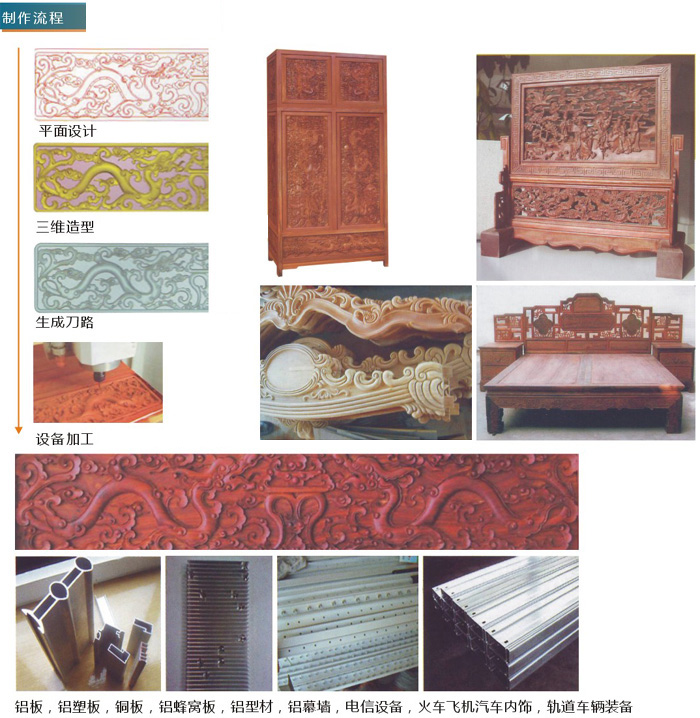

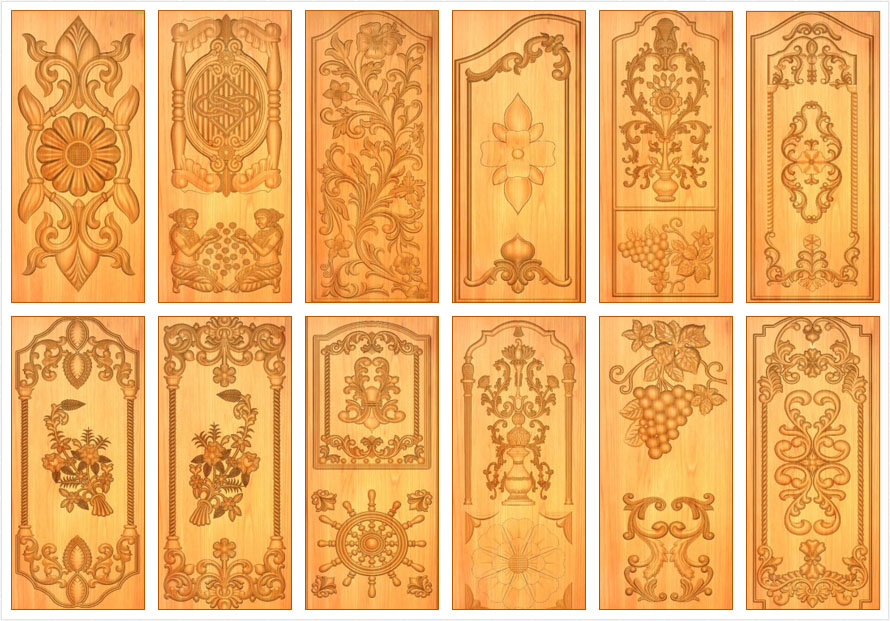

3轴木工雕刻机可以用于雕刻和切割一些材料:实木,石材,金属,玻璃,泡沫,PVC,亚克力等。 产品应用于家具,厨具,橱柜,模具制造,航空航天,轨道交通,电子等。

雕刻机,

CNC Router, CNC Router Machine, Wood Carving Machine, CNC Machine, Engraving Machine; used to engrave and cut on wood, MDF, PVC, foam, acrylic, stone, marble, aluminum;

Automatic Feeding Nesting CNC Router for Cabinet Making CNC Furniture Making Machine Nesting Machine for Sale;

7' x 10' CNC Router w/ Vacuum Table and Linear Tool Changer

Increase precision and productivity in your production shop.

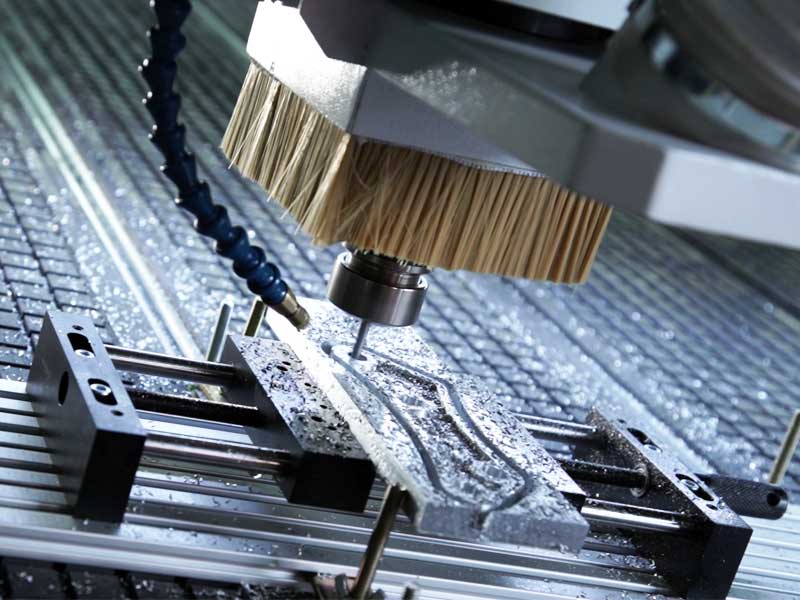

The CNC Router is a unique machine. it can cut in 3D.

From small surface engraving to large organic shapes, this machine will truly allow your creativity to run wild.

Featuring a linear automatic 8-tool changer, this is the most advanced CNC router we offer, capable of machining complex surfaces over the entire surface of the 4' x 8' bed.

The table has four independently controlled vacuum zones to secure your workpieces during cutting operations.

The compact and user-friendly Nc studio/LNC/Syntec/Siemens Sinumerik 808D Advanced control is a panel-based CNC controller for basic turning and milling applications.

This machine is compatible with many common CAD/CAM platforms including. If you are wanting a more in-depth overview of the design software used with machine, please contact with us and watch video on how to get started with CNC.

Increase your shop’s production with this value-packed CNC machine.

Like all of the computer numeric controlled machines, the machine comes with a 3-year warranty covering parts and assuring the unit is free from factory defects (Consumables are not covered by the warranty); we have 21 years Customer Service experience and professional Technical Support Teams.

Parts and accessories for the CNC machine may be available online and shipped by fedex from china.

Made in an ISO 9001 factory

CE certified

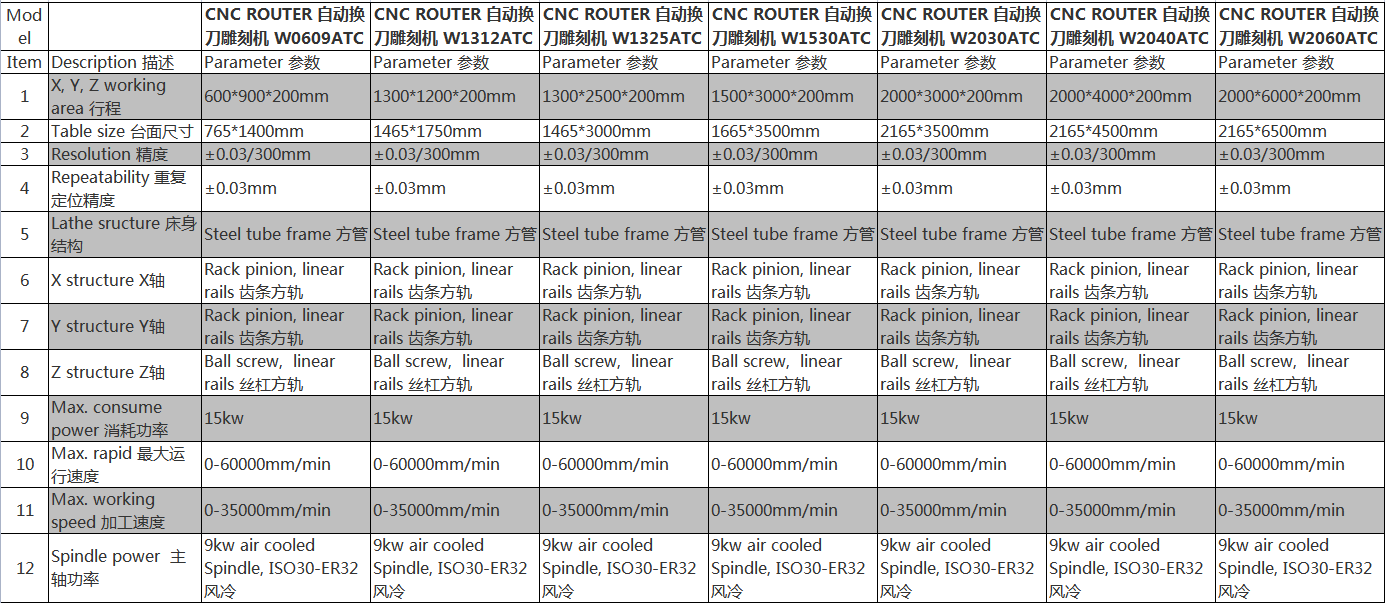

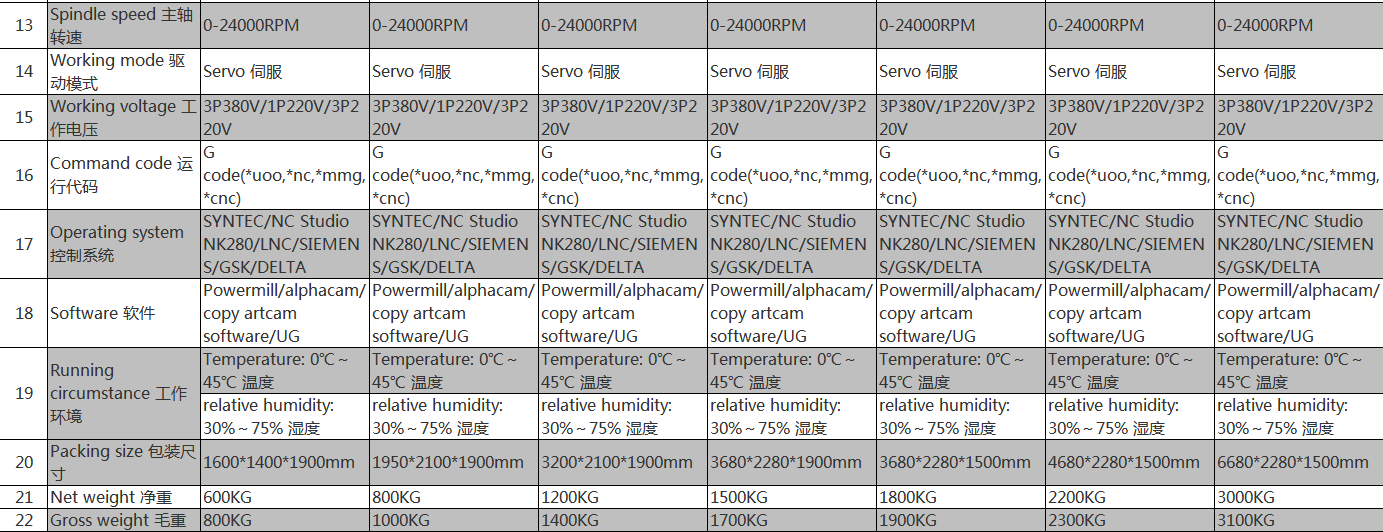

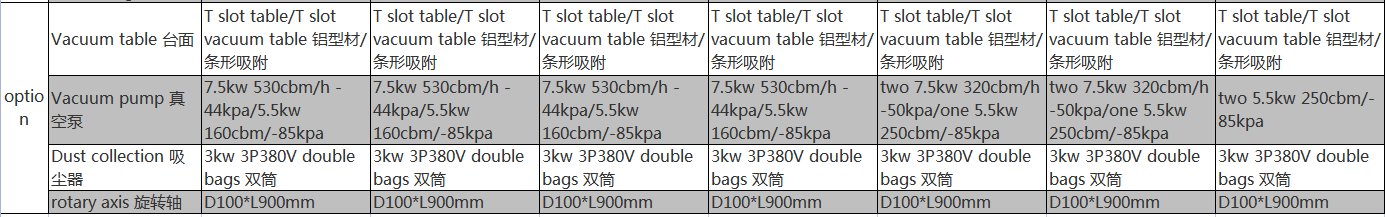

SPECIFICATIONS:

Spindle motor: 12HP 9KW, 220V, 3-phase, 24.3A 24000rpm

boring drilling bank unit: 5+4 vertical drills

Axis motors: Servo Motor, 3.0A

X-Axis working size: 2135mm

Y-Axis working size: 3050mm

Z-Axis working size: 200mm

XY- rapid speed: 75m/min

Z- rapid speed: 20m/min

Cutting accuracy: +/-0.03

Collet: ER32M 1/4", 1/8", 4mm, 6mm

FEATURES:

NC stuido/LNC/Syntec/Siemens Sinumerik 808D Advanced with built-In digital display and input

Linear automatic 8-tool changer or carousel

air-cooled spindle motor

Vacuum table with six independently controlled zones

Tool touch-off pad for quickly setting Z-axis height

Two-stage air vacuum pump (requires separate 3-phase, 220V hardwire connection)

Automatic oiler for bearing rails

Helical rack-and-pinion X- and Y- gantry travel, Z ball screw;

ACCESSORIES:

Collets: 1/4", 1/8", 4mm, 6mm

Open-end 41/46 wrench

ER32 collet wrench

Six T-track hold down clamps

Vacuum table plugs

Dust collection shoe with hose attachment

Due to product size, this item must be delivered to a loading dock or unloaded with a forklift. Liftgate not available.

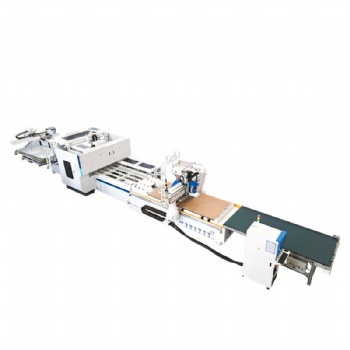

Description:

This type of nesting CNC router is your best choice for furniture production. With the automatic tool change function and automatic loading and unloading functions, the production efficiency is greatly improved.

this is professional nesting making machine with an auto-feeding system. This nesting machine is ideal for mass production in the furniture industry.

Features:

1. With automatic loading and unloading platform, it can effectively improve the production efficiency of cabinets and panel furniture. With an automatic labeling function, the machine can quickly recognize the workpieces’ position and conduct precise processing.

2. This nesting machine adopts HQD or CC 9kw ATC spindle or the new Italian ES951 air-cooled tool change spindle, the speed can reach 24000 rpm, and it has the advantages of strong cutting ability and long service life.

3. With Italian HSD 9 vertical drills, multiple vertical holes can be processed at one time, effectively improving the drilling efficiency.

4. With 8 high-speed disc tool magazines, tool change can be completed within 8 seconds, which effectively improves production efficiency.

Application:

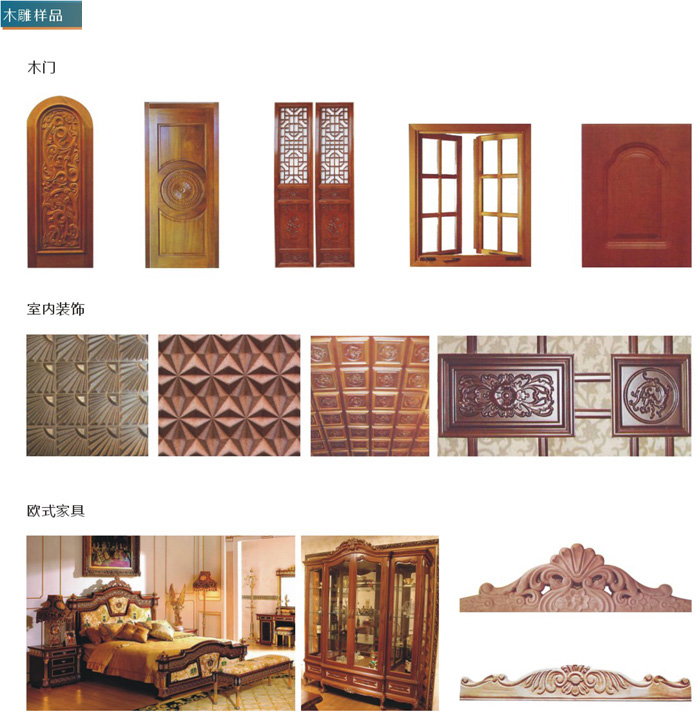

It is mainly used to cut various wooden boards. In terms of processing functions, the cutting machine mainly includes cutting, punching, grooving, and other processes. The nesting CNC machine is widely used in the furniture industry such as cabinet doors, wardrobe doors, solid wood doors, paint-free doors, solid wood composite doors, and suite doors.

Material:

Wood: natural wood, plywood, soft wood, hard wood, fiberboard, particle board, melamine board, LDF, MDF, chipboard;

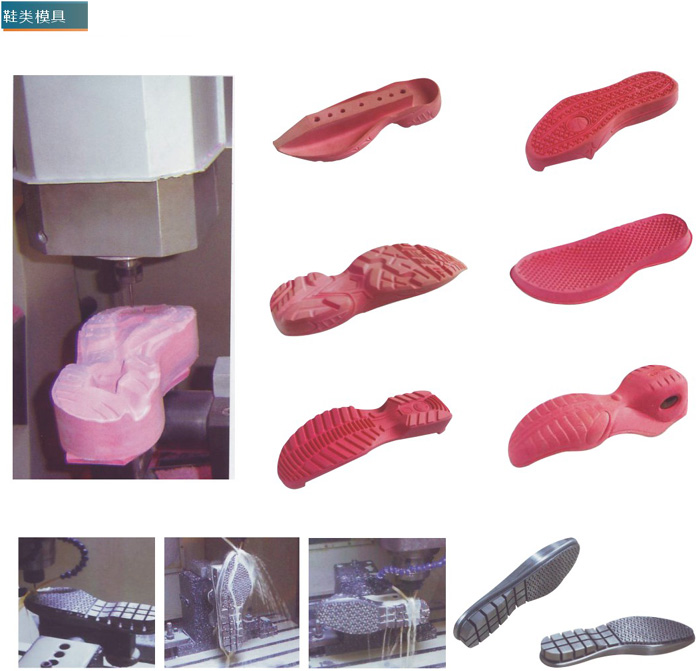

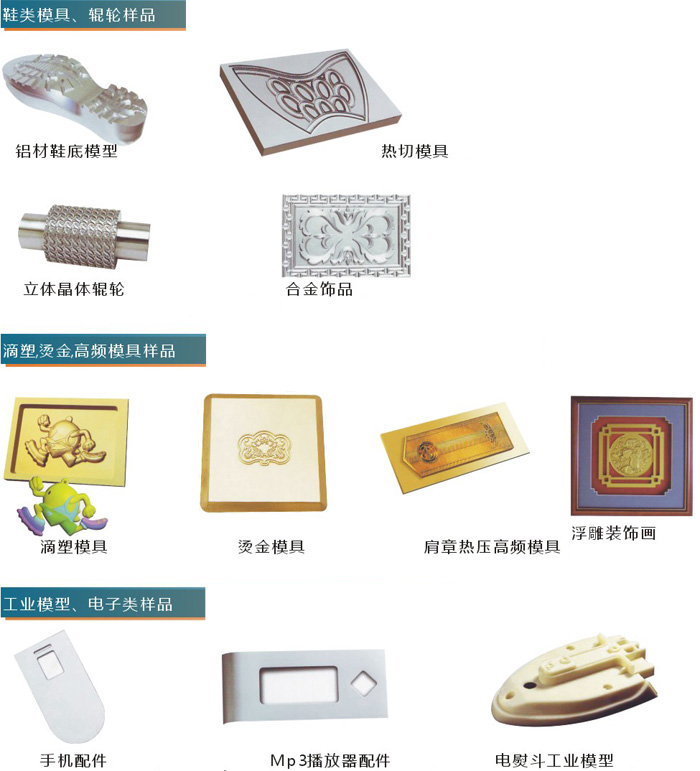

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA;

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones;

Soft metal: aluminum, brass, copper, mild steel;

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite;

产品目录

联系我们

- +86-531-88586516

- +86-531-88586517

- +86-18653142760

- [email protected]

- maxryli

- +86-18653142760

售前客服

售前客服